How to Make a Stunning Epoxy River Table: Step-by-Step Guide

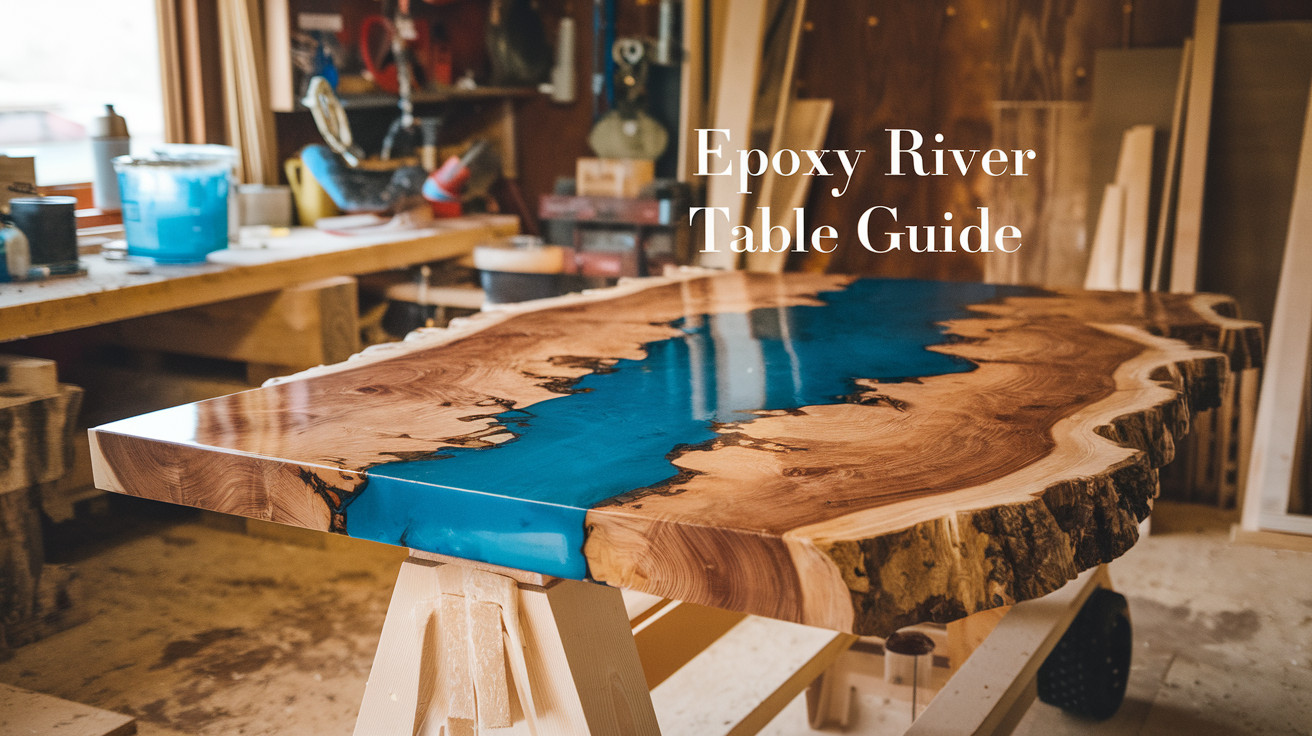

Have you ever dreamed of owning a unique, eye-catching piece of furniture that’s both functional and a work of art? 🎨 Look no further than the epoxy river table! These stunning creations have taken the interior design world by storm, offering a perfect blend of natural beauty and modern aesthetics.

Imagine a table where shimmering, translucent “rivers” of epoxy flow between rugged wooden banks, creating a mesmerizing landscape right in your living room. 🌊🌳 But here’s the exciting part: you can make one yourself! With the right tools, techniques, and a bit of patience, you can craft a one-of-a-kind masterpiece that will be the envy of all your guests.

In this step-by-step guide, we’ll walk you through the entire process of creating your very own epoxy river table. From understanding the basics and preparing your workspace to selecting the perfect wood, pouring the epoxy, and adding those final touches, we’ve got you covered. So, roll up your sleeves and get ready to embark on a creative journey that will transform a simple slab of wood into a conversation-starting centerpiece for your home!

Understanding Epoxy River Tables

What is an epoxy river table?

An epoxy river table is a stunning piece of furniture that combines the natural beauty of wood with the sleek, modern look of epoxy resin. These tables feature two pieces of wood, often with live edges, separated by a flowing “river” of colored epoxy resin. The result is a unique, eye-catching centerpiece that brings the outdoors inside.

Benefits of creating your own

Creating your own epoxy river table offers numerous advantages:

- Customization: Design a table that perfectly fits your space and style

- Cost-effective: Save money compared to purchasing a pre-made table

- Satisfaction: Experience the pride of crafting a high-quality piece of furniture

- Skill development: Learn valuable woodworking and resin pouring techniques

- Unique artwork: Create a one-of-a-kind conversation starter for your home

Essential tools and materials

To embark on your epoxy river table project, you’ll need the following tools and materials:

| Tools | Materials |

|---|---|

| Circular saw or table saw | Wood slabs |

| Sander | Epoxy resin |

| Mixing containers | Pigments or dyes |

| Measuring cups | Wood sealer |

| Stirring sticks | Silicone mold release |

| Heat gun or torch | Sandpaper (various grits) |

| Protective gear (gloves, goggles, mask) | Finishing products (oil, varnish, etc.) |

| Clamps | Plastic sheeting |

| Level | Tape |

When selecting your wood slabs, consider using live edge pieces for a more organic look. Popular wood choices include:

- Walnut

- Oak

- Maple

- Cherry

- Elm

For the epoxy resin, choose a high-quality, clear casting resin suitable for deep pours. Ensure it’s food-safe if you plan to use the table for dining.

Now that we’ve covered the basics of epoxy river tables, their benefits, and the essential tools and materials needed, you’re ready to start preparing your workspace for this exciting project. The next section will guide you through setting up a suitable area for creating your stunning epoxy river table.

Preparing Your Workspace

Now that we understand what epoxy river tables are, let’s focus on setting up the perfect workspace for your project. Proper preparation is crucial for achieving stunning results and ensuring a smooth workflow.

A. Choosing the right location

Selecting an appropriate location for your epoxy river table project is essential. Consider the following factors:

- Size: Ensure the space is large enough to accommodate your table, tools, and materials.

- Ventilation: Choose a well-ventilated area to minimize exposure to fumes from epoxy and other chemicals.

- Temperature: Maintain a consistent room temperature between 70-80°F (21-27°C) for optimal epoxy curing.

- Lighting: Adequate lighting is crucial for detecting imperfections and ensuring even epoxy application.

B. Setting up a dust-free environment

Creating a dust-free workspace is vital for achieving a flawless epoxy finish. Follow these steps:

- Clean thoroughly: Vacuum and wipe down all surfaces in your work area.

- Cover surfaces: Use plastic sheeting or drop cloths to protect floors and nearby objects.

- Create barriers: Set up temporary walls or curtains to isolate your workspace from other areas.

- Use air filtration: Install an air purifier or fan with a filter to remove airborne particles.

C. Organizing your tools and materials

Proper organization of your tools and materials will streamline your workflow and prevent mistakes. Here’s a checklist to help you get started:

| Category | Items |

|---|---|

| Protection | Safety goggles, respirator, nitrile gloves |

| Mixing | Mixing containers, stir sticks, digital scale |

| Application | Spreaders, brushes, torch or heat gun |

| Sanding | Orbital sander, sandpaper (various grits) |

| Finishing | Polishing compounds, buffing pads |

| Miscellaneous | Tape measure, level, clamps, tarp |

Arrange your tools and materials in a logical order, keeping frequently used items within easy reach. Consider using a rolling cart or workbench for added convenience and mobility.

By meticulously preparing your workspace, you’ll create an environment conducive to crafting a stunning epoxy river table. A clean, organized, and well-equipped workspace will not only improve the quality of your final product but also make the entire process more enjoyable and efficient.

With your workspace now ready, we’ll move on to the next crucial step: selecting and preparing the wood for your epoxy river table project.

Selecting and Preparing the Wood

Now that you have your workspace ready, it’s time to focus on the heart of your epoxy river table: the wood. This step is crucial as it will determine the overall look and durability of your finished piece.

A. Choosing the right type of wood

Selecting the perfect wood for your epoxy river table is essential. Hardwoods like oak, maple, and walnut are popular choices due to their durability and beautiful grain patterns. Here’s a comparison of some common wood types:

| Wood Type | Durability | Grain Pattern | Color |

|---|---|---|---|

| Oak | High | Prominent | Light to medium brown |

| Maple | High | Subtle | Pale cream to light brown |

| Walnut | Medium-high | Distinctive | Dark brown |

| Cherry | Medium | Fine, straight | Reddish-brown |

Choose a wood that complements your design vision and fits your budget. Remember, the wood’s natural edges will create the unique “river” effect in your table.

B. Cutting and shaping the wood slabs

Once you’ve selected your wood, it’s time to cut and shape it:

- Use a chainsaw or bandsaw to cut the wood into two slabs.

- Create a live edge by carefully removing the bark while preserving the natural contours.

- Shape the slabs to your desired dimensions, ensuring they fit your table design.

C. Sanding and cleaning the wood surface

Proper sanding is crucial for a smooth finish and strong epoxy bond:

- Start with coarse-grit sandpaper (60-80 grit) to remove any rough spots.

- Gradually move to finer grits (120, 220, 320) for a smooth surface.

- Clean the wood thoroughly to remove all dust and debris:

- Use a tack cloth or compressed air to remove loose particles.

- Wipe down with mineral spirits to remove any oils or residues.

D. Creating the river channel

The river channel is where your epoxy will flow, creating the stunning visual effect:

- Arrange your wood slabs on a flat surface, leaving a gap for the “river.”

- Use painter’s tape to outline the river’s path if you want precise edges.

- If desired, create depth variations in the channel for a more natural look:

- Use a router or chisel to carve deeper sections.

- Add rocks or other elements to create interesting contours.

Remember to seal any knots or cracks in the wood with a thin layer of epoxy to prevent air bubbles in your final pour. This preparation stage sets the foundation for a stunning epoxy river table. With your wood now ready, you’re one step closer to creating a unique piece of functional art that will be the centerpiece of any room.

Mixing and Pouring the Epoxy

Now that you’ve prepared your wood and workspace, it’s time for the exciting part: mixing and pouring the epoxy. This step is crucial in creating a stunning epoxy river table that will become the centerpiece of any room.

A. Calculating the required amount of epoxy

Before you begin mixing, it’s essential to calculate the exact amount of epoxy needed for your project. Here’s a simple formula to help you:

- Measure the length, width, and depth of your river in inches

- Multiply these three measurements together

- Divide the result by 231 (cubic inches in a gallon)

- Add 10% for overflow and waste

| Table Size | River Dimensions | Epoxy Needed |

|---|---|---|

| 6′ x 3′ | 72″ x 6″ x 2″ | 1.25 gallons |

| 8′ x 4′ | 96″ x 8″ x 2″ | 2.22 gallons |

B. Selecting the right color for your river

Choose a color that complements your wood and fits your overall design aesthetic. Popular choices include:

- Deep blue for a water-like appearance

- Metallic gold or copper for a luxurious look

- Clear epoxy to showcase the wood grain underneath

C. Mixing the epoxy resin and hardener

Follow these steps for perfect epoxy mixing:

- Measure the resin and hardener according to the manufacturer’s instructions

- Mix thoroughly for 3-5 minutes, scraping the sides and bottom of the container

- Pour the mixture into a clean container and mix again for another 2-3 minutes

D. Pouring techniques for a smooth finish

To achieve a flawless pour:

- Start by sealing any gaps in the wood with a thin layer of epoxy

- Pour the epoxy slowly and steadily, starting from one end of the river

- Use a heat gun or torch to remove air bubbles as you pour

- Continue pouring in layers, allowing each to partially cure before adding the next

E. Adding decorative elements (optional)

Enhance your epoxy river table with unique elements:

- Incorporate metallic flakes for a shimmering effect

- Add glow-in-the-dark pigments for a night-time surprise

- Embed small objects like pebbles or seashells for texture

Remember to work quickly but carefully, as epoxy has a limited working time. With these techniques mastered, you’re well on your way to creating a stunning epoxy river table. Next, we’ll explore the crucial curing and finishing process to ensure your table’s longevity and beauty.

Curing and Finishing

Now that you’ve successfully poured your epoxy resin, it’s time to focus on the crucial steps of curing and finishing your epoxy river table. This stage is where your creation truly comes to life, transforming from a raw pour into a stunning piece of functional art.

A. Proper curing time and conditions

Ensuring proper curing is essential for the durability and appearance of your epoxy river table. Here’s what you need to know:

- Curing time: Most epoxy resins require 24-72 hours for initial curing, but full curing can take up to 7 days.

- Temperature: Maintain a consistent room temperature between 70-80°F (21-27°C) during the curing process.

- Humidity: Keep humidity levels below 70% to prevent moisture-related issues.

| Curing Stage | Time | Temperature | Humidity |

|---|---|---|---|

| Initial Cure | 24-72 hours | 70-80°F (21-27°C) | Below 70% |

| Full Cure | Up to 7 days | 70-80°F (21-27°C) | Below 70% |

B. Removing air bubbles

Even with careful pouring, some air bubbles may appear during the curing process. Here’s how to address them:

- Use a heat gun or torch to pop surface bubbles within the first few hours of pouring.

- Gently pass the heat source over the surface, being careful not to overheat the epoxy.

- For stubborn bubbles, use a toothpick to carefully bring them to the surface.

C. Sanding the cured epoxy surface

Once fully cured, it’s time to sand your epoxy river table for a smooth finish:

- Start with coarse-grit sandpaper (80-120 grit) to level any high spots.

- Progress through medium grits (220-400) to remove scratches from coarser grits.

- Finish with fine-grit sandpaper (600-1000) for a silky-smooth surface.

- Use an orbital sander for large areas and hand-sand edges and intricate parts.

D. Applying a protective finish

To enhance durability and bring out the beauty of your epoxy river table, apply a protective finish:

- Choose your finish: Options include polyurethane, lacquer, or a specialized epoxy topcoat.

- Application methods:

- Brush-on for small areas or detailed work

- Spray-on for a more even coat on larger surfaces

- Pour-on for a thick, glass-like finish

- Multiple coats: Apply 2-3 thin coats, sanding lightly between each for the best results.

Remember, patience is key during the curing and finishing process. Rushing these steps can compromise the quality of your final product. With careful attention to detail, you’ll soon have a stunning epoxy river table ready for its base and final placement in your home or office.

Adding the Table Base

Now that your epoxy river table top is cured and finished, it’s time to add the base. This crucial step will transform your beautiful creation into a functional piece of furniture. Let’s explore how to choose, attach, and stabilize your table base.

Choosing a Complementary Base Design

Selecting the right base is essential for both aesthetics and functionality. Consider these factors when choosing your table base:

- Style compatibility with the tabletop

- Material harmony (metal, wood, or a combination)

- Weight capacity to support the heavy epoxy top

- Room aesthetics and overall decor

Here’s a comparison of popular base materials:

| Material | Pros | Cons |

|---|---|---|

| Metal | Sturdy, modern look, thin profile | Can be expensive, may scratch floors |

| Wood | Matches tabletop, warm aesthetic | Requires more maintenance, bulkier |

| Hybrid | Best of both worlds, unique look | Can be complex to design and build |

Attaching the Base Securely

Proper attachment is crucial for the longevity and safety of your epoxy river table. Follow these steps:

- Mark attachment points on the underside of the tabletop

- Pre-drill holes for screws or bolts

- Apply wood glue for additional strength (if using a wooden base)

- Use appropriate hardware (e.g., lag bolts for metal bases, wood screws for wooden bases)

- Tighten all connections, ensuring they’re snug but not over-tightened

Ensuring Stability and Level Surface

A wobble-free, level table is the hallmark of quality craftsmanship. Here’s how to achieve it:

- Use a spirit level to check the tabletop’s flatness

- Adjust the base or add shims if necessary

- Install adjustable feet on the base for easy leveling on uneven floors

- Double-check stability by applying pressure to different areas of the table

Remember, the base is not just a functional element but also an integral part of your table’s design. A well-chosen and properly attached base will complement your epoxy river tabletop, creating a stunning piece of furniture that’s both beautiful and durable.

As we wrap up the construction of your epoxy river table, it’s important to consider how to maintain and care for your new masterpiece to ensure its longevity and continued beauty.

Maintenance and Care

Now that you’ve created your stunning epoxy river table, it’s essential to maintain its beauty and durability for years to come. Proper care and maintenance will ensure your table remains a centerpiece in your home, showcasing the unique blend of wood and resin craftsmanship.

Cleaning your epoxy river table

Keeping your epoxy river table clean is relatively simple but requires attention to detail. Here’s a step-by-step guide to cleaning your table effectively:

- Dust regularly with a soft, lint-free cloth

- Use a mild soap solution for deeper cleaning

- Avoid abrasive cleaners or rough materials

- Dry immediately after cleaning to prevent water spots

For stubborn stains, consider using specialized epoxy cleaners, but always test on an inconspicuous area first.

Protecting from heat and sunlight

Epoxy resin is sensitive to heat and prolonged exposure to direct sunlight. To protect your table:

- Use coasters or trivets for hot items

- Avoid placing the table in direct sunlight

- Consider UV-resistant window films if near windows

- Rotate decorative items periodically to prevent uneven fading

| Temperature | Effect on Epoxy |

|---|---|

| < 120°F | Generally safe |

| 120-150°F | May soften |

| > 150°F | Risk of damage |

Addressing minor scratches or damages

Over time, your epoxy river table may develop minor scratches or damages. Here’s how to address them:

-

For light scratches:

- Use a fine-grit sandpaper (2000 grit or higher)

- Gently sand the affected area

- Polish with a specialized epoxy polishing compound

-

For deeper scratches or chips:

- Clean the damaged area thoroughly

- Apply a small amount of clear epoxy resin

- Allow to cure and sand smooth if necessary

Remember, prevention is key. Use felt pads under decorative items and be cautious when moving objects across the table surface.

By following these maintenance and care tips, your epoxy river table will continue to be a stunning focal point in your space. Regular cleaning, protection from heat and sunlight, and prompt attention to any damages will ensure your DIY masterpiece remains beautiful for years to come. As we move forward, you’ll find that the time invested in caring for your epoxy table is well worth the effort, preserving the unique blend of wood and resin that makes your creation truly one-of-a-kind.

Creating an epoxy river table is a rewarding journey that combines craftsmanship with artistic expression. From selecting the perfect wood to pouring the vibrant epoxy, each step contributes to a unique and stunning piece of functional art. By following this guide, you’ve learned how to prepare your workspace, mix and pour epoxy, and finish your table to perfection.

As you embark on your own epoxy river table project, remember that patience and attention to detail are key. Take your time with each step, and don’t be afraid to let your creativity shine through. With proper maintenance and care, your epoxy river table will be a conversation piece and a cherished addition to your home for years to come. Now, it’s time to gather your materials and bring your vision to life!

TubShroom Ultra Revolutionary Bath Tub Drain Protector Hair Catcher/Strainer/Snare Stainless Steel, 1-Pack, Silver

$11.99 (as of June 6, 2025 01:24 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Refrigerator Deodorizer,Lasts for 10 Years,Refrigerator Odor Eliminator,Fridge Deodorizer,More Effective Than Baking Soda Bamboo Air Purifying Bags

$24.99 (as of June 6, 2025 01:25 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Medguy Medical Nitrile Exam Gloves, 4.5 Mil 100 Pcs, Powder-Free Latex-Free Food-Safe Cooking Cleaning Disposable Glove, Blue

$5.83 (as of June 6, 2025 01:24 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Home-it Mop and Broom Holder Wall Mount Garden Tool Storage Tool Rack Storage & Organization for the Home Plastic Hanger for Closet Garage Organizer (5-position)

$14.99 (as of June 6, 2025 01:25 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Akro-Mils 44-Drawer Plastic Drawer Storage Cabinet for Garage Organization, Bead Organizer, Building Bricks Storage, Teacher Toolbox, Makeup Organizer, 20-Inch W x 6-Inch D x 16-Inch H, 10144 Black

$39.99 (as of June 6, 2025 01:25 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)SAMSUNG Genuine Filter for Refrigerator Water and Ice, Carbon Block Filtration, Reduces 99% of Harmful Contaminants for Clean, Clear Drinking Water, 6-Month Life, HAF-QIN/EXP, 1 Pack

$38.49 (as of June 6, 2025 01:24 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)everydrop by Whirlpool Ice and Water Refrigerator Filter 1, EDR1RXD1, Single-Pack , Purple

$43.90 (as of June 6, 2025 01:24 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Auto Amazon Links: No products found. WEB_PAGE_DUMPER: The server does not wake up: https://web-page-dumper.herokuapp.com/ URL: https://www.amazon.com/gp/top-rated/zgbs/ Cache: AAL_120777e93bee31084f2bc595674a00ae